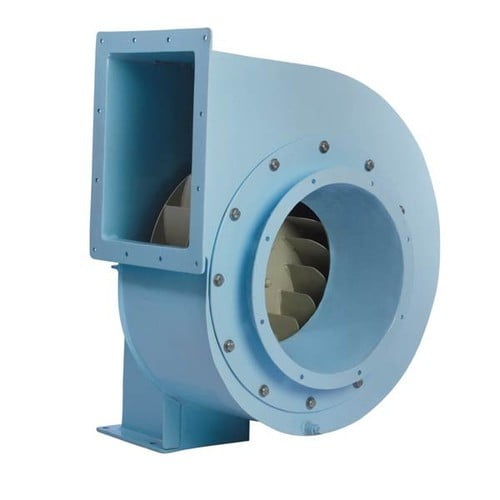

“VENTILAIR INDIA PVT.LTD.” offers High efficiency induced draft fans with Mild Steel and Stainless Steel construction. Our Fans are suitable for even toughest of the Industrial conditions and are used in various industries such as boiler, chemical, dust collection, pharma, marine, packaging, etc.

Ventilair India has vast experience as an induced draft Fan manufacturer, supplier & exporter. Our fans are widely used by manufacturers of boilers, furnaces, dust collection, and ovens with their equipment. All the impellers are statically and dynamically balanced on the machine. A balancing and fan performance certificate is provided along with the blower. Ventilair makes Induced Draft Fan and Forced Draft Fan are designed to run at high efficiency thereby giving considerable power savings to our customers.

Features of Induced Draft Fans:-

2. High Impeller Life

3. Less Maintenance

4. Low noise

5. High Bearing Life

6. Good after sales service

Frequently Asked Questions (FAQs):

What is an Induced Draft Fan (ID Fan)?

An Induced Draft Fan (ID Fan) is a mechanical device used in industrial and power plant boilers to create a negative pressure or suction, drawing combustion gases through the boiler’s exhaust system and up the chimney.

What is the purpose of an ID Fan?

The primary purpose of an ID Fan is to improve combustion efficiency by removing flue gases, ensuring proper air and fuel mixing, and preventing backflow of gases into the boiler.

How is an ID Fan different from a Forced Draft Fan (FD Fan)?

An ID Fan operates on the exhaust side of a boiler to pull gases, while a Forced Draft Fan (FD Fan) operates on the intake side to supply air for combustion. ID Fans create a negative pressure, while FD Fans create positive pressure.

What industries use Induced Draft Fans?

Induced Draft Fans are used in a wide range of industries, including power generation, petrochemical, chemical processing, pulp and paper, and any industry requiring efficient combustion and exhaust gas removal.

How do I select the right Induced Draft Fan for my application?

Choosing the right ID Fan involves considering factors like boiler size, operating conditions, gas flow rate, and pressure requirements. It’s best to consult with a fan manufacturer or an engineer to ensure proper fan selection based on your specific needs and system parameters.